Research and Application Development

We don't wait for new innovations, we engineer them. From concept to commissioning.

Acuren’s Research and Application Development specializes in the development of advanced Ultrasonic inspection techniques and system for challenging inspection applications, with an emphasis on practical solutions which are field deployable. Our group is comprised of experienced Ultrasonic application development engineers with particular expertise in the following areas:

The Research and Applications Development group is composed of researchers with expertise in:

- Phased Array ultrasonic Testing (PAUT)

- Time-of-Flight-Diffraction (TOFD)

- Signal and Image Processing

- Probability of Detection (PoD) Study

- Machine Learning, Statistical Analysis of UT Data

- Full Matrix Capture (FMC)

- Total Focusing Method (TFM)

- Ultrasonic Modeling using CIVA

- Ultrasonic Inspections at Elevated Temperatures

- Inspection/Analysis Procedure Development

- Services Offered

- Past Successes

- Current Initiatives

- Technique and procedure development for Eddy Current/Eddy Current Array/Pulsed Eddy Current, Phased Array Ultrasonic Testing based inspections at ambient and elevated temperatures: we can develop an inspection technique from scratch all the way through to code qualified. Our team will find the optimal inspection parameters using a combination of modelling (CIVA/COMSOL/Beamtool) and experiment, as well as provide setups, calibration procedures and a full POD/sizing accuracy study to fully evaluate the proposed solution (as required). We also have intimate familiarity with all relevant codes and procedures required for technique qualification.

- Full-Matrix Capture/Total Focusing Method based technique development/refinement: The Research and Applications Development group has been working with FMC/TFM for over 3 years and has gained considerable insight into how to best optimize FMC based inspection techniques. We can recommend the best probe/wedge/acquisition unit combinations as well as the best rendering paths to make any FMC based inspection successful.

- Design and manufacture of ultrasonic wedges (including high temperature wedges), calibration blocks and scanning equipment: the Research and Applications Development group has considerable experience in the design of NDT equipment/apparatus with in house machining and fast prototyping capabilities.

- Probability of detection and sizing accuracy studies: full validation of any NDT technique using Eclipse Scientific’s STATUS POD software.

- Ultrasonic characterization of materials: precise measurement of acoustic velocities, attenuation and dispersion characteristics of any test specimen.

- Feasibility studies: short term proof of concept type studies, aimed at providing customers with evidence that a proposed inspection methodology is likely to be successful and is worth further research.

- High Resolution UT Immersion Scanning: Research and Applications Development has a fully equipped, multi-axis immersion tank scanning system and can provide high resolution ultrasonic inspection of complex parts.

- Custom Software and Algorithm Design: our expertise in signal/image processing and machine learning applied to NDT inspections coupled with Eclipse Scientific’s industry leading software team can provide customized solutions for the acquisition, processing and analysis of NDT data.

- Inspection technique was developed and optimized using CIVA models.

- Designed wedges were manufactured.

- Custom scanner was developed for scanning small fillet welds.

- Inspection procedure was developed for field deployment.

- Analysis procedure was developed for inspection data analysis.

- Technique was successfully deployed in field for the customer.

- Automated detection and sizing algorithms developed and proven effective.

- Initial technique development using BeamTool

- Initial proof of concept using CIVA Models for probe, wedge and technique optimization

- Preparation of Inspection Qualification Plan document outlining required tests and sample test for full Probability of Detection (PoD) study

- Preparation of Factory Acceptance Tests (FAT) for initial evaluation of the manufactured tool based on PAUT inspection capabilities

- Performing full probability of Detection (PoD) and sizing accuracy study and preparation of Technical Justification (TJ) Document for CIQB qualification

- Technical justification and inspection technique was successfully delivered

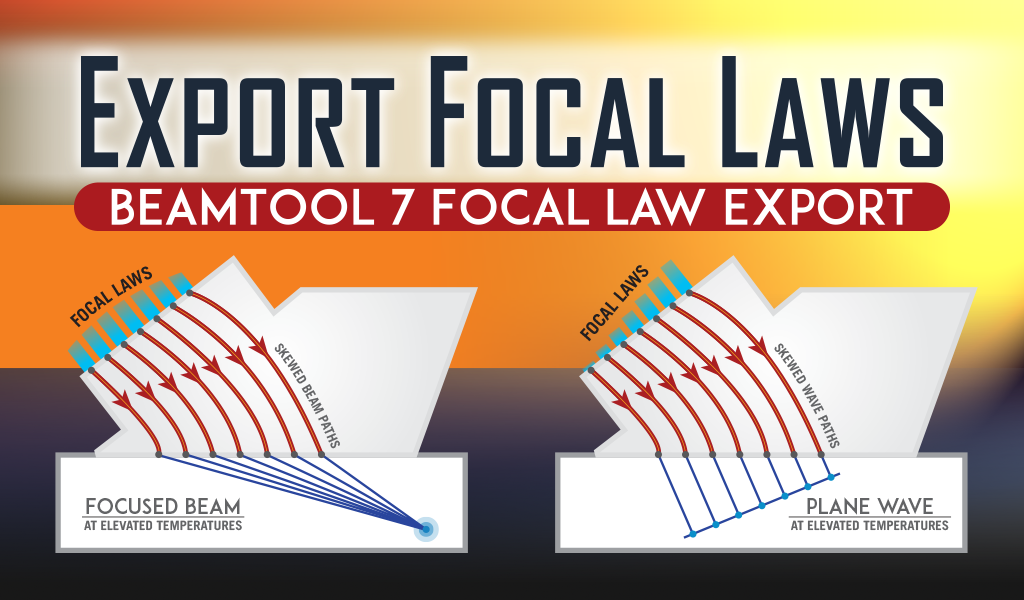

- A model of the ultrasonic beam skew pattern due to thermal gradient inside a wedge is developed

- Model results are used to obtain transmission and reception time delays on individual elements for generation of a plane waves or focused beams in a hot test piece while compensating for thermal gradient inside the wedge.

- BeamTool high temperature module has been prepared for exporting the custom transmission-reception time delays in law file format readable by conventional phased array instruments.

- Performance of the developed phased array inspection system has been fully validated including the effect of using the custom law files in proper positioning of defects detected at elevated temperatures

- The Inspection system is currently being successfully used widely in industrial sites for inspection of engineering components at elevated temperatures.

Services offered by the Research and Applications Development team include:

Full Matrix Capture (FMC) Inspection of Fillet Welds for lack of fusion detection

We developed an inspection system based on Full Matrix capture data acquisition and Total Focusing Method (TFM) imaging algorithm for volumetric inspection of the fillet welds, detection of lack of fusion and quantifying/sizing disboning on the weld fusion face.

Design and qualify of a Phased Array Ultrasonic Testing (PAUT) inspection tooling for full volumetric examination of tube welds.

Research and Applications Development in partnership with Acruen Nuclear Services, designed a tooling for phased array inspection of tube welds. The scope of work included:

Development of Phased Array Inspection system for Weld Inspection and corrosion mapping at Elevated Temperatures up to 350 Celsius.

Research and Applications Development in partnership with Eclipse Scientific developed a phased array inspection system to be used for inspections at elevated temperatures. The inspection system includes wedges designed for use at elevated temperatures and build from plastics resistant to high temperature degradation and equipped with a cooling jacket around the array. Temperature effects on generated ultrasonic beams at elevated temperatures have been fully studied and compensated for.

Inspection of Near Surface Delamination and Forging Defects using Focused Linear Scanning and Rayleigh Waves

We recently concluded a project in which the first 10 mm of a forged component was to be inspected for small de-laminations (~ 0.5 mm). Using a combination of high frequency, highly focused linear scans as well as relatively low frequency Rayleigh wave inspection, full coverage of the inspection range was demonstrated. Machined targets as small as 0.5 mm in a range of 1-10 mm from the component’s surface were repeatably detected using the proposed PAUT technique, while targets as small as 0.5 mm in the first 3 mm from the surface were reliably detected using Rayleigh wave inspection. A 1 mm target located 2 mm below the component’s surface, detected by both the PAUT and Rayleigh wave techniques is shown in the figure below.

The technique was developed using an OmniScan MX 1, off the shelf probes and a custom profiled wedge which was designed and manufactured by the Research and Applications Development group.

In addition to ongoing funded research projects, the Research and Applications Development group is also developing new technologies/techniques aimed at solving some of the most challenging inspection problems in the NDT industry as identified by Acuren’s subject matter experts. Our current research initiatives include:

Development of High Temperature FMC Inspection

Full matrix capture inspection is increasingly deployed in situations where high resolution scans offer benefits for detection and sizing of small defects. In particular, TFM images have been found to provide quantitative information regarding the progression of high temperature hydrogen attack (HTHA) at room temperature. Since HTHA is commonly found in reactors operating at elevated temperatures, there exists considerable interest in running FMC scans at temperatures above 200 Celsius. Having previously developed high temperature wedges/scanners for PAUT inspections, the Research and Applications Development group is now investigating the potential of adapting these systems to FMC based inspections. Initial scans indicate that without applying any modifications to the TFM algorithm to compensate for temperature induced velocity gradients in the wedge and piece, FMC scans can be performed up to around 300 C with only minor distortions in the target images, as shown in the images below:

It is noted that the background noise increases considerably at high temperatures, that may interfere with the detection of HTHA which manifests as elevated material noise. The increase in background noise is likely caused by localized flashing of the high temperature couplant layer. Consequently, the team is looking into alternative coupling mechanisms capable of delivering better scan quality at very high temperatures. In addition, the team is working on modifying the delay calculations required for applying the TFM algorithm in the presence of a wedge velocity gradient using travel-time tomography. The end goal is to have a fully functional FMC/TFM system which can be deployed to obtain high resolution images of components at temperatures up to 350 C.

PAUT Scanning with Custom Pitch/Catch Focal Laws – Application to Root Erosion Monitoring and Stress-Corrosion Crack Depth Estimation

In an effort to strike a balance between the improved resolution achievable with FMC/TFM and the cost effectiveness/scanning speed/deployability of traditional phased array systems, we have been working to develop custom focal laws which produce highly focused images of narrow regions of interest. These laws can be imported into common phased array acquisition units. This approach has been found to be very promising for two particular applications: monitoring/sizing of weld root erosion and depth estimation of stress corrosion cracking (SCC).

For the case of weld root erosion monitoring a pitch/catch PAUT arrangement is used with focal laws designed to focus shear waves along the nominal centerline of the weld, which allows regions of root erosion to be easily detected and the extent of erosion readily estimated, as seen in the figure below.

A similar focal law has been used in an attempt to focus shear waves along the face of surface breaking cracks, with the ultimate goal of estimating the extent of SCC cracks (as shown in the figure below).

Using a 3D printed inspection jig (made in house), the technique has been used to accurately size surface breaking notches, as shown in the image below:

The way that the resulting focal law is plotted in standard PAUT analysis software (Zetec’s Ultravision Software) shows the vertical extent of the notches along the horizontal axis. Further work is underway to determine the precise sizing accuracy of the proposed technique. In addition, the possibility of including a second group using a different focal law which involves another backwall skip is being investigated by the Research and Applications Development group.

Advanced Phased Array Processing

FMC/TFM technology provides ultrasonic images with much higher resolution as compared to standard phased array images. Accordingly, FMC/TFM offers clear benefits in terms of flaw interpretation and sizing. FMC/TFM based inspections have 3 major limitations: 1. processing speed, 2. storage requirements and 3. limited pulsing energy (only a single element is used at a time in transmission). All of these shortcomings can limit the practical inspection range, which is particularly problematic as FMC/TFM is becoming commonly used for HTHA inspections of thick reactor walls. The Research and Applications Development group has developed a novel algorithm which processes standard phased array sectorial sweeps into high resolution images which rival those obtained by applying the TFM to FMC data. The following images compare the resolution of angled holes on a Harfang block obtained using FMC/TFM and the advanced PAUT processing algorithm (2 groups of 32 elements used in the sectorial sweep, +/- 60 degrees, 1 degree increment).

A major advantage of the proposed algorithm is that it can be run using standard acquisition units (OmniScan, Topaz, etc.). In addition, scan files are only slightly larger than for a typical PAUT sweep which allows for the possibility of rendering the higher resolution images live for large inspection ranges (data transfer and rendering algorithm can be fast enough). In addition, the fact that a large aperture is used in transmission allows more energy to be generated in the piece, which can help penetrate deeper, specifically in noisy materials.

Bounce Path Attenuation and Attenuation Rate Tomography for Imaging Microstructural Damage

Many defect types do not reflect ultrasound with appreciable energy and thus cannot be imaged using traditional UT techniques. Such types of defects, which can be microstructural in nature can manifest as inhomogeneity in the ultrasonic attenuation (or the frequency dependence thereof) within a component. The Research and Applications Development group has developed a technique capable of mapping subtle changes in attenuation to produce cross-sectional images of pieces suspected of localized microstructural damage. The technique is a straightforward adaptation of computed tomography (CT) scanning, commonly used in medical ultrasound to image soft tissue, where projection data are instead obtained by looking at the back-wall response between element pairs on a phased array probe (operating in Full Matrix Capture mode) with respect to a healthy reference sample. The technique has been used successfully to image small clusters of microporosity (10 micron pores) introduced into a small aluminium sample, as shown below.

The hope is that this technique will prove effective for imaging other types of microstructural damage such as HTHA and early stage creep, as well as other types of non-reflecting defects, such as poor fusion of plastic pipe welds and defects in friction stir welds. Additionally, this technique has been found to be a promising new approach for imaging/sizing surface connected cracks. The image below shows the ability of attenuation tomography to accurately size, tight, surface connected notches.

An obvious application for surface connected crack sizing is the depth estimation of SCC crack colonies, which the Research and Applications Development group is actively investigating at the present moment.

Through Cap PAUT Inspection of Fillet Welds with Flexible Polymer Wedges

Currently no commonly accepted technique exists for inspecting fillet welds for lack of fusion or volumetric defects. To that end, we have developed a technique which uses wedges made of flexible polymers to scan directly through the weld cap, focusing along the nominal fusion face or the center of the weld volume, depending on what type of weld defect is to be inspected. Coupling is achieved using a thin ethanol film which when pressed between the weld cap and the flexible wedge material achieves acceptable acoustic transmission. The following image shows the detection of incomplete weld penetration and crack like defects found in a FlawTech T-weld sample.

Further work is currently underway to establish and evaluate an appropriate sizing technique.

For more information, email us at

rad@acuren.com

or call (519) 372-1831 and ask for

one of our innovation experts