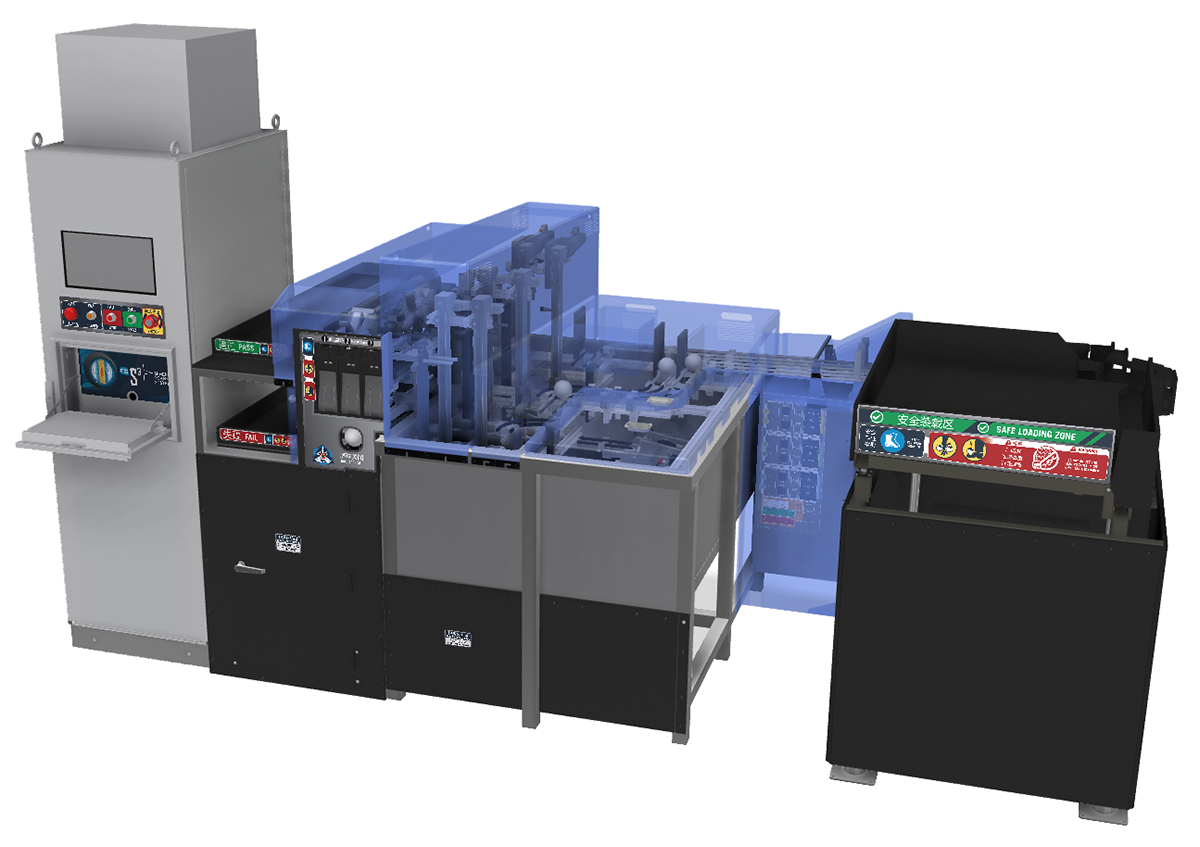

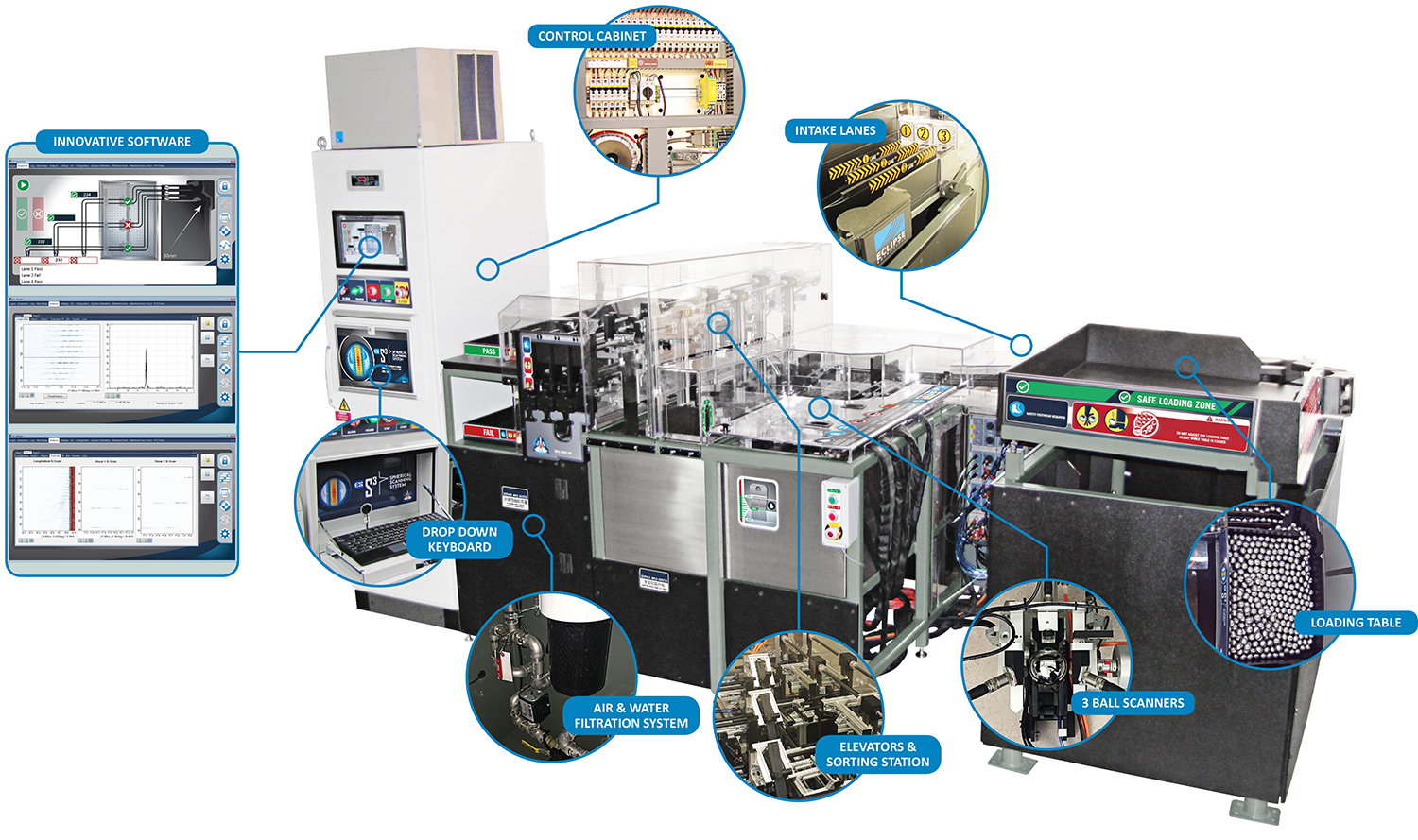

- Overview

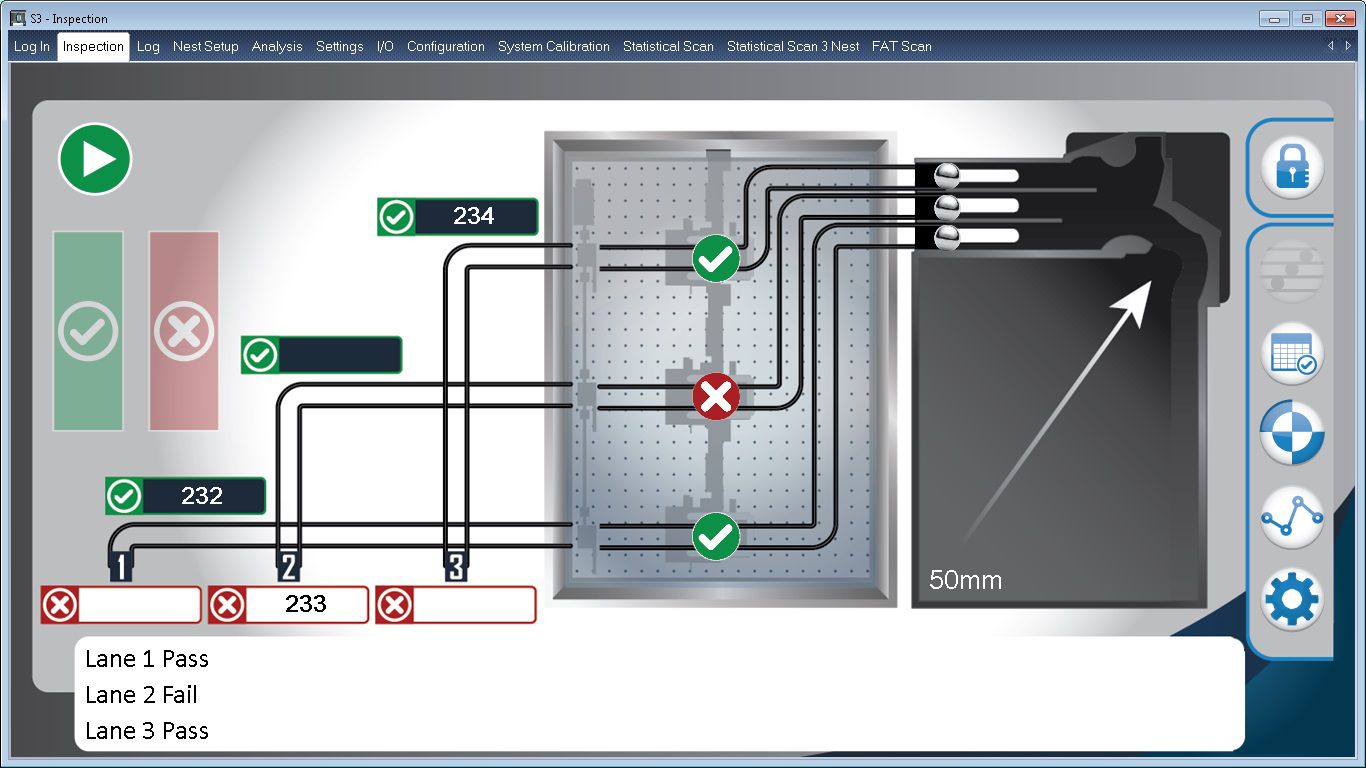

- Software

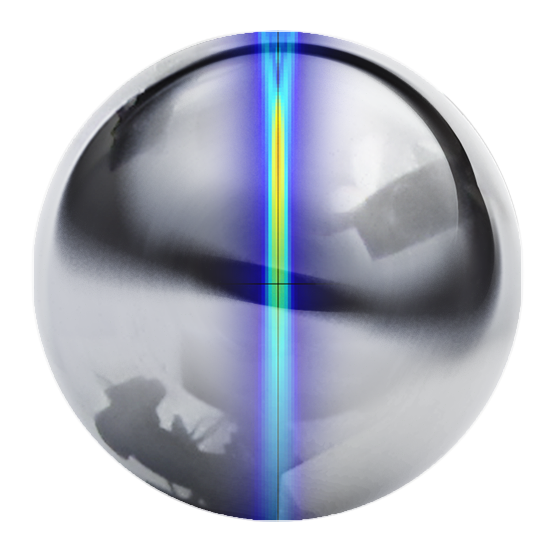

- UT Technology

- Extra

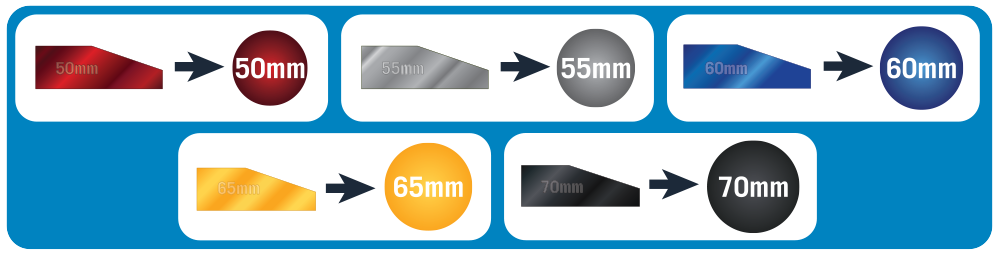

- Bearing Balls Diameter: 50, 55, 60, 65 and 70 mm

(contact us for custom size requirements) - Loading Table Capacity: 500 balls

- UT Inspection: Full volumetric with high probability of detection of flaws > 0.5mm diameter

- Inspection Rate: 2-3 balls per minute

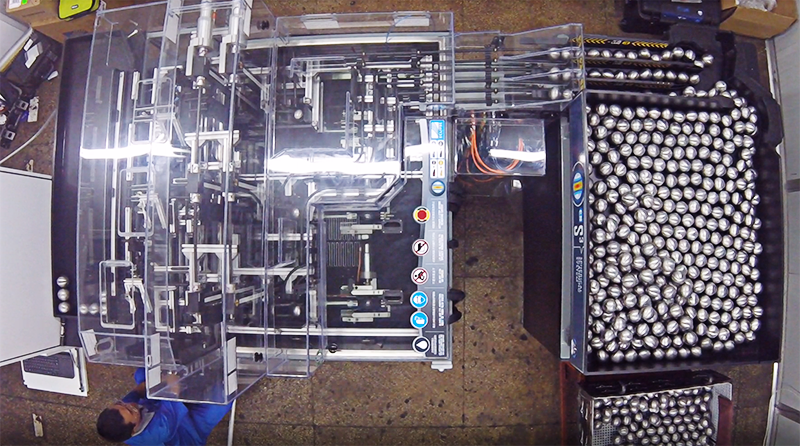

- Fully automated scanning and sorting of balls into pass or fail trays

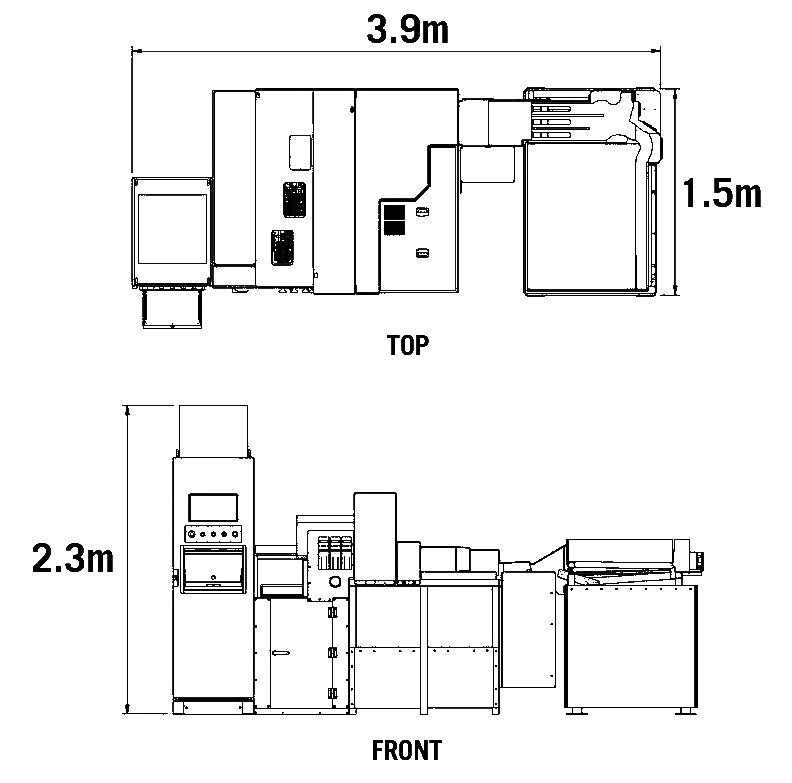

- Overall dimensions: 3.9m x 1.5m x 2.3m

- Weight: 1200 kg

- Power Input: 220-240 V (110-120 V available), 50 – 60 Hz auto-sensing

- Pneumatic: 100 PSI, 1 cfm

- UPS: 3000 VA / 2.7 kW

- Cooling Unit: 8000 BTU

- Operational Requirements: 18°C – 24°C / 40% – 70% humidity

- Storage Requirements: 0°C – 40°C / 20% – 80% humidity non-condensing

- Immersion Tank Capacity: 550 Liters

- 40 micron pneumatic filter with auto-drain liquid reservoir

- Designed for industrial environments, the S3 system contains a fully enclosed digitally controlled cooling system that is not affected by external air quality.

- A fully online UPS and Surge arrestor protects the system from surges, spikes, and other power disturbances.

- 16 Channel conventional UT

- 300V square wave pulser

- 25 MHz bandwidth

- 100 MHz sampling, 12 bits vertical resolution

- 4-axis encoder input

- 15 Mhz

- Point focused

- Powerful PC with Intel Core i7 4.0 GHz processor, 16 GB RAM, and 12 TB HDD

- Separate 256 GB Solid HDD for fast OS boot-up & operation

- 16 Channel Ultrasonic pulser/extremely low noise receiver and 4-axis encoder input for extremely high speed scanning

- Powerful, low noise linear motor amplifiers and power supplies for interference free operation

- Uninterrupted Power Supply (UPS) with power conditioner

- Power Surge Protection

- Closed cooling system for reliable system performance

- Convenient touch sensitive monitor

- Heavy duty fold away keyboard tray

- Lockable equipment cabinet doors for security

- Password protected digital thermostat

- Long life 10 micron water filtration and UV filter

- Heavy duty industrial water circulation pump

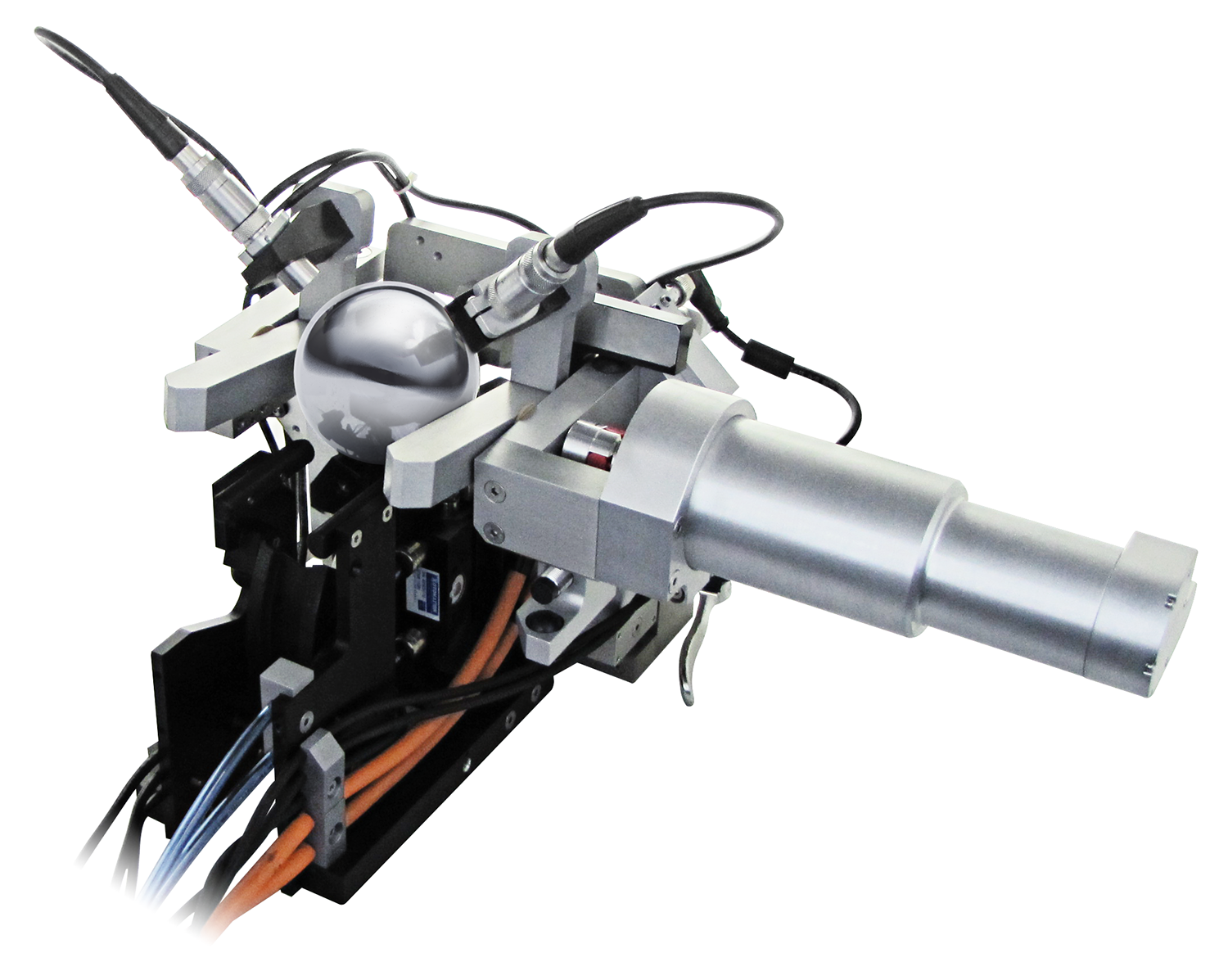

- Adjustable pneumatic actuators for fine control

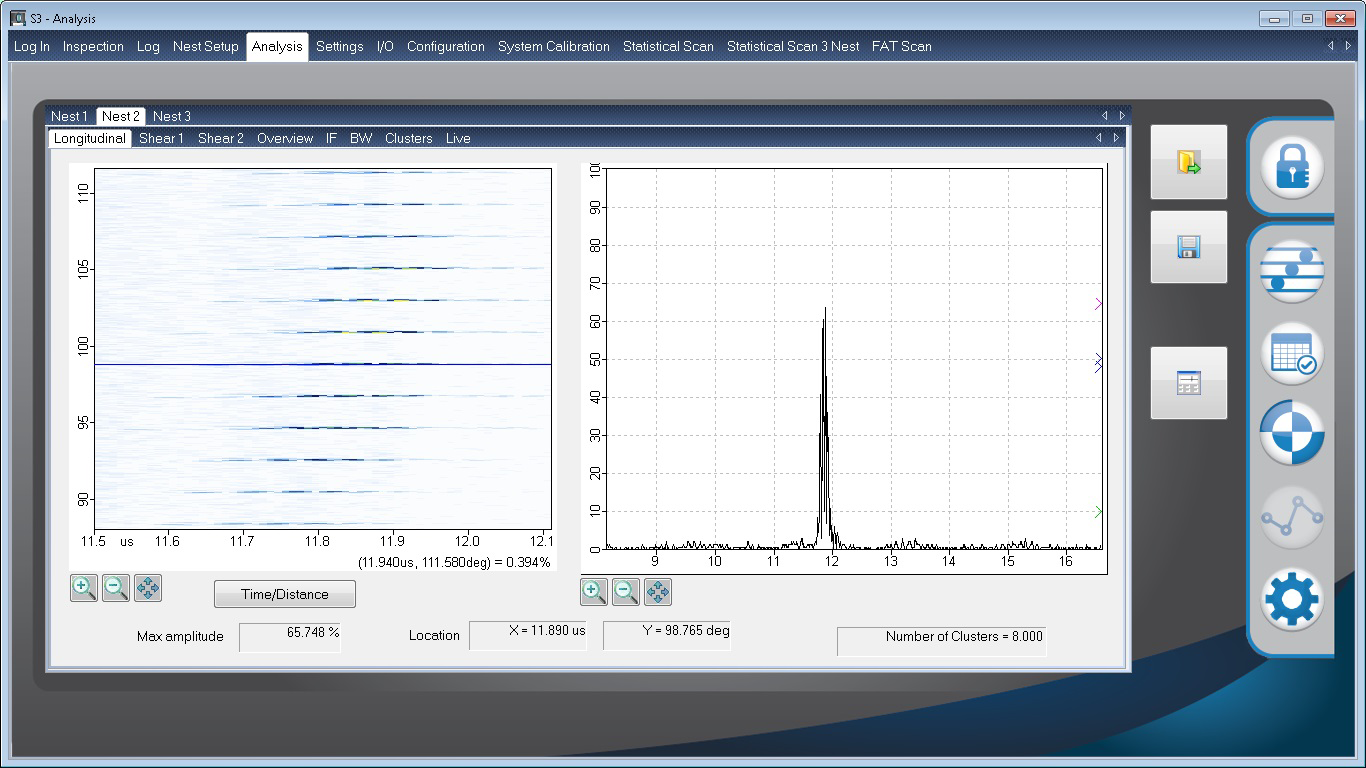

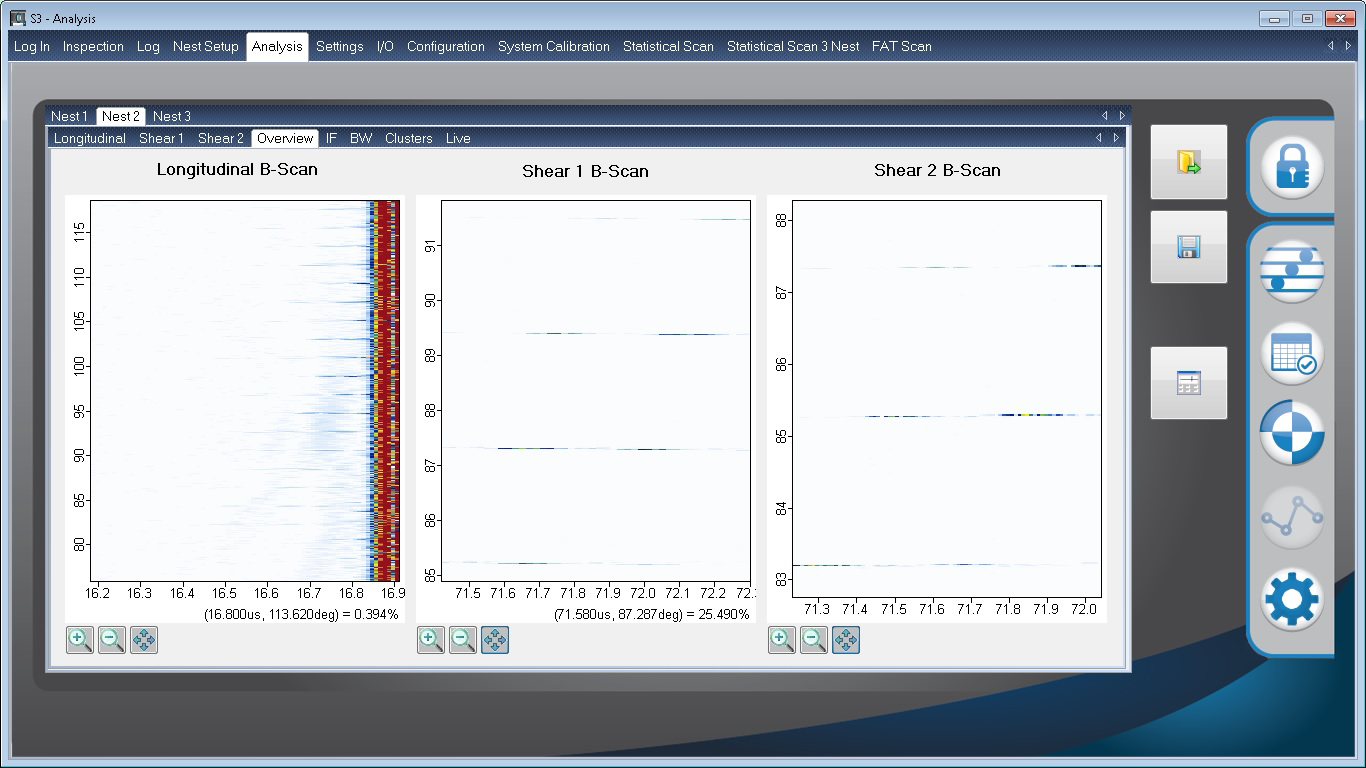

Intuitive Software

Intuitive software interface allows users to monitor and control the inspection process as well as generate reports of scan activities including detailed inspection data, dates, fail-pass status, and calibration. Inspection database and high resolution data files allow analysis of ball failure modes.

Advanced Engineering

Data Acquisition

Transducers